Services

All services are managed in-house by our own specialist team who have many years of experience in plastic injection moulding

Design

We start with how the product will be used to determine the design. It is an exacting process for the plastic injection mould designer to find the best solution and we will take everything into account from walls, ribs, gussets, depressions etc. Our knowledge and advice can save you from an expensive mistake.

Tooling

Once you’re happy with the design the process of injection moulding tooling begins. We can give you advice on polymers, flow rates and what type of mould is best for your production needs. A top quality tool will keep your production costs to an absolute minimum.

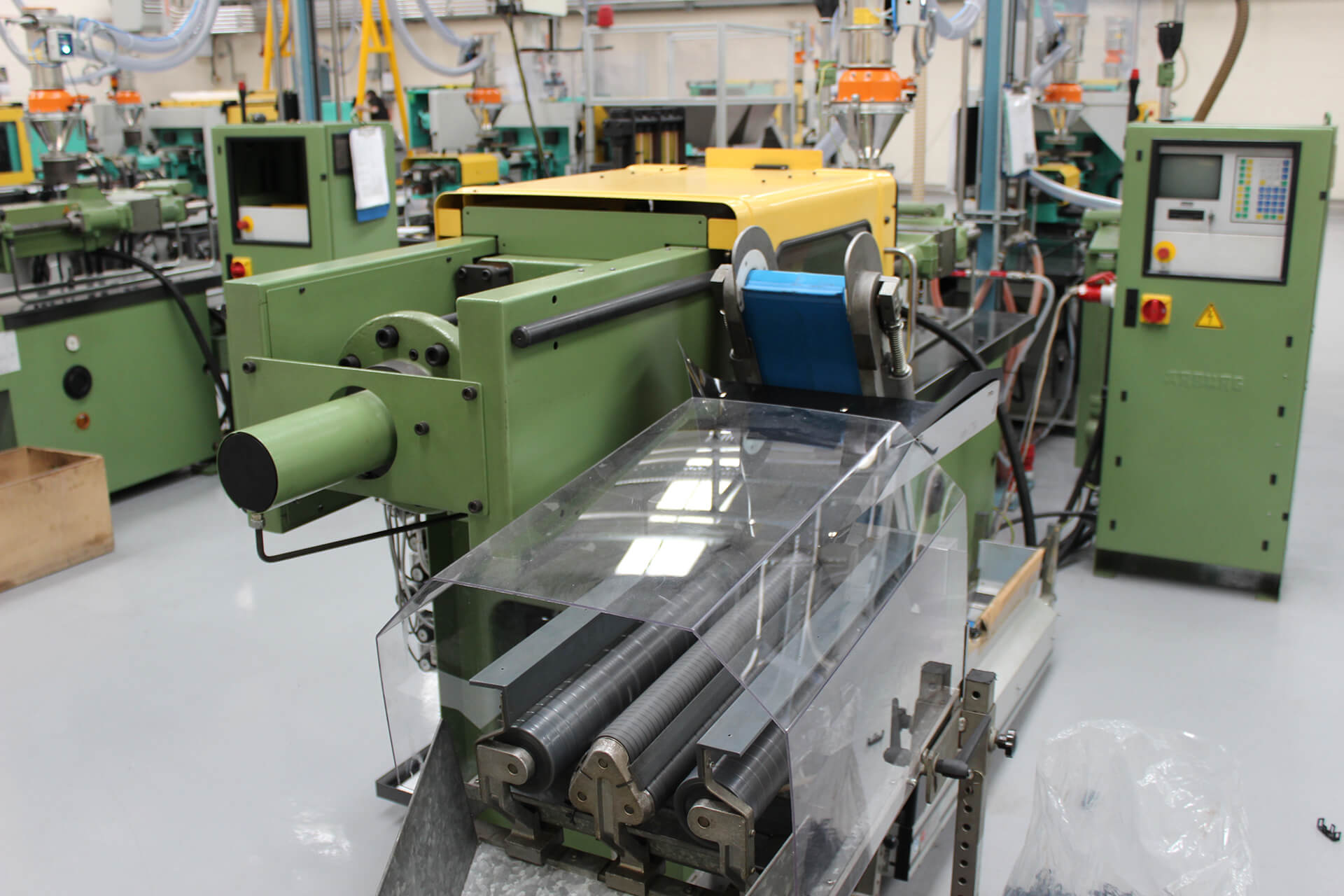

Moulding

This is where we get to the detail of how your plastic moulded parts will actually be produced. We can advise on thickness, weight, surface area etc to make sure that you have the best quality injection moulded product for your needs.

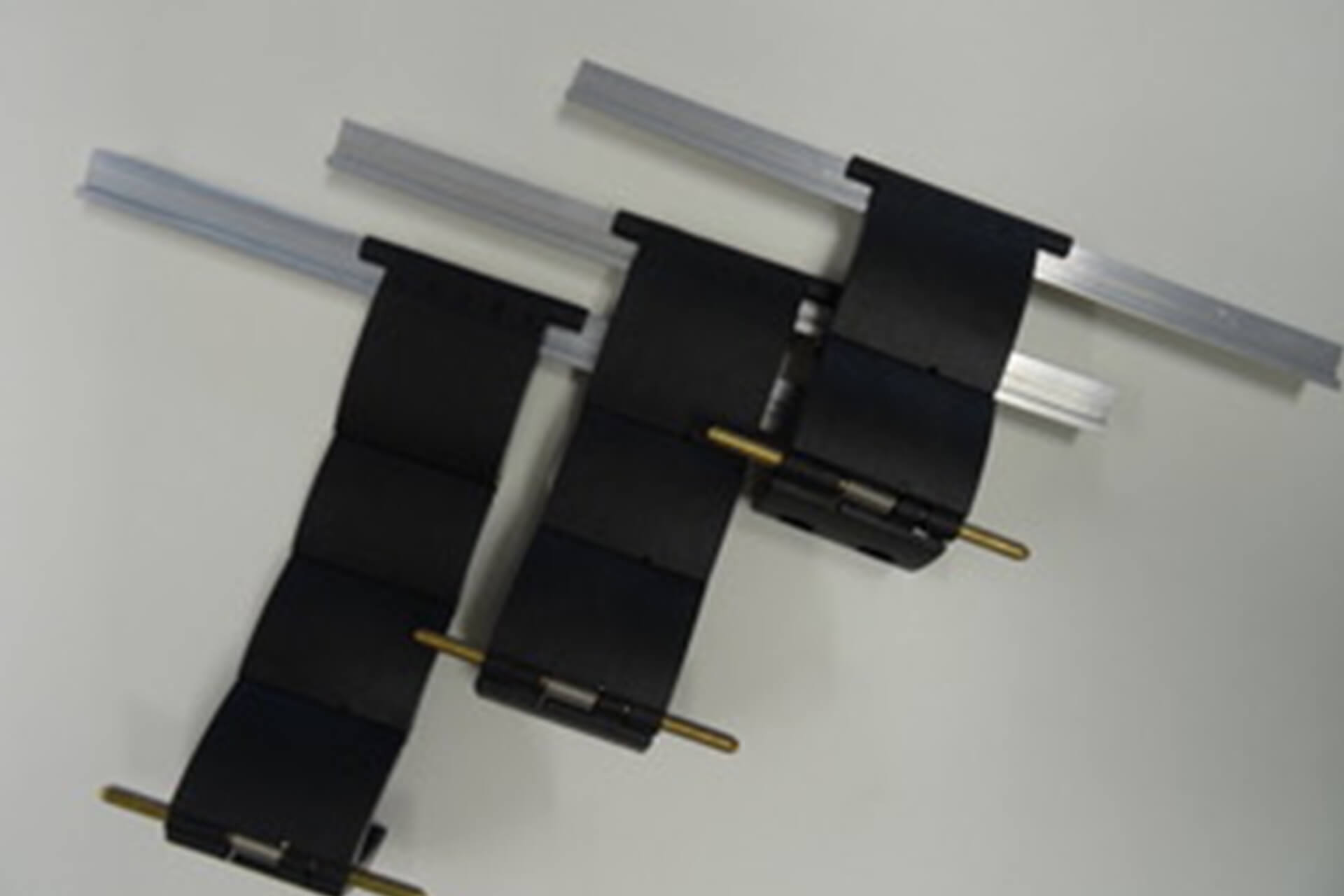

Assembly

Our quality assurance process means that your components will be assembled in a clean environment and examined for any signs of stress or impurity. This is carried out at agreed intervals for all injection moulding products.

Testing

Precision is key and we agree the testing process for each product with every client individually. The success of injection moulding is all down to whether the component will do what it needs to do under real conditions.

Warehousing

Your tool is kept on site in a secure and separate area. We can also store your products and we have a drawdown facility in place for plastic injection moulded components which is subject to size, weight and dimensions and agreed drawdown and delivery arrangements.